The easiest way to clean the nozzle of a 3D printer

|

On FDM 3D printers, many components contribute to the printout, but the nozzle is perhaps one of the most important. It is where the molten material leaves the hotend. If you don't know much about this part, here's a summary - the nozzle usually has a thread to connect to the hotend and a smaller hole at the other end to push the filament through. The nozzle is important mainly because it affects the extrusion of the filament. And if it's not working properly, it can lead to a number of annoying printing problems. Additionally, not all nozzles are created equal. The performance and lifetime of the nozzle is determined by aspects such as material, diameter and other properties. Nothing lasts forever, and that includes jets. They deteriorate over time, especially when they become dirty, clogged or overused. Therefore, it is important to clean the nozzle regularly and ensure that it works well with other parts of the printer such as the hotend located on the print head. And in addition, this will also extend the life of the nozzle. In this article, we will look at how to properly clean the nozzle and prevent those problems. But also how to solve any problems that could put your printer out of service. |

Recognizing the problem

Before we get into the issue of cleaning the nozzle, it is important to make sure that the problem really lies in the nozzle. Below are a few problems that can be caused by a dirty nozzle. There are other factors involved with each of these that need to be checked first before determining the type of fault.

- The first layer does not print

If you turned on the print, but you can't see filament coming out of the nozzle, it may be caused by a clogged nozzle. However, it's also a good idea to check if this problem is caused by the extruder, the Z offset setting, or the printing pad in the wrong position.

- The nozzle picks up the already printed filament

This problem occurs when the nozzle prints some material and then picks it up randomly as it moves across the print layer. Usually the nozzle is the only cause of this problem, but just to be sure, make sure you have the Z offset set correctly and the print pad in the correct position.

- Filament stuck at the hotend

The filament often gets stuck or caught in the middle and lower areas of the hotend. Since the nozzle is part of the hotend, it could be responsible for this. But don't forget to check whether the cause of this problem is in the hotend (e.g. in the PTFE insert).

- Inconsistent filament extrusion

Inconsistent extrusion usually looks like the printer can't keep up with filament extrusion. It then ends up extruding material in sudden bursts, even though it should be extruding an even amount of filament. However, make sure that this problem is not caused by wet filament or the extruder's stepper motor (specifically, its power).

- Underextrusion

Under-extrusion is a similar problem to the one described above, but a milder version where prints tend to be printed with parts missing. Again, make sure the problem isn't caused by wet filament, loose extruder tension, or an uneven filament path.

- Missing print

If you start a print and come back after a while expecting a finished print and instead find a print with only a few (if any) layers printed, this may be due to a clogged nozzle. But don't forget to check that the filament diameter is correct, the print temperature is in the correct range for the particular filament material, and the extruder is spinning (it's ok if no filament is being extruded, but you need to check that the extruder motor is working).

As already mentioned, it is necessary to first recognize the nozzle as the source of the problem. While cleaning the nozzle is usually not a bad idea, it may not solve your printing problems. The ideal way to effectively solve a printing problem is to consider each potential cause of the problem. Then proceed from the simplest check to the most complex. Investigate every possible cause to find the real culprit. Once you are sure that a dirty nozzle is indeed causing the printing problem, move on to the cleaning methods.

Dirt on the outside of the nozzle

Dirt stuck to the outside of the nozzle is an unmissable problem. Debris is usually excess molten filament that has stuck to the nozzle during printing. This problem is almost always caused by the nozzle being set too low. And often when printing the first layer, the problem becomes even worse, because the rule of thumb is that material adheres best to the same material. Basically, as the filament flows out of the nozzle, some of it can stick to the nozzle, and gradually become more attached to the original material that has already stuck to the outside of the nozzle.

What is the solution?

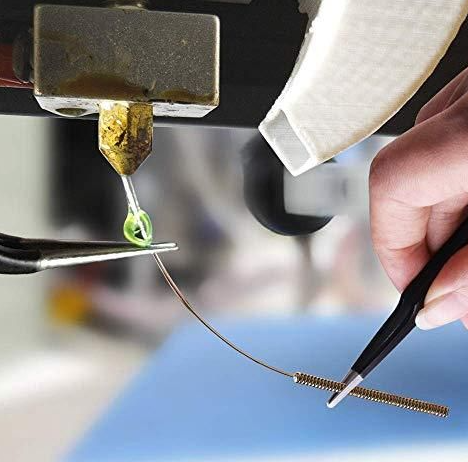

First, clean the nozzle with a damp cloth (or a cloth soaked in alcohol), ideally while the nozzle is still hot. This may result in some steam coming out of the nozzle, but the important thing is that any material stuck to the nozzle is removed. If this procedure does not work, you can also use a wire brush , a small knife or a needle to remove the remaining dirt from the nozzle .

You already know how to clean the outside of the nozzle, but prevention is the best - prevent any material from getting on the nozzle. So consider increasing the Z-offset value (calibrating the gap between the nozzle and the printing pad) and aligning the printing pad. Another thing that can help is using a silicone sleeve to cover most of the nozzle and prevent too much material from sticking.

Clogged nozzle

Nozzle clogging is perhaps the most common problem encountered with nozzles. This can occur when filament debris inside the hotend blocks the nozzle outlet, preventing additional filament from exiting (resulting in insufficient filament extrusion or, worse, a missing portion of the print).

There are two types of nozzle clogging: partial clogging and complete clogging. As you may have guessed, a completely clogged nozzle is the worst case scenario. Impurities block the entire outlet opening and thus trap the filament in the extruder. A partial blockage occurs when debris blocks only part of the outlet opening. Which is a slightly better option, but you still need to clean the nozzle thoroughly.

What is the solution?

There are several methods for solving a clogged nozzle, and we'll go over three of them.

- The first and easiest is to stick a small needle into the nozzle to loosen and then push out the debris.

- The second method is "Cold pull". This option is suitable if your nozzle is only partially blocked. Instructions for this method can be found here .

- The third method is to completely replace the clogged nozzle. This method is economically painless if you use ordinary brass nozzles, which are not expensive. For this method, start by heating the hotend to melt any solidified material stuck in the nozzle. And also make sure you remove any filament that is fed into the extruder. As soon as the clogged filament softens due to the heat, unscrew the nozzle from the hotend. Before attaching the new nozzle, make sure to clean the hotend carefully (you can use a needle to remove excess stuck filament). A nozzle replacement and maintenance kit may come in handy for replacing the nozzle .

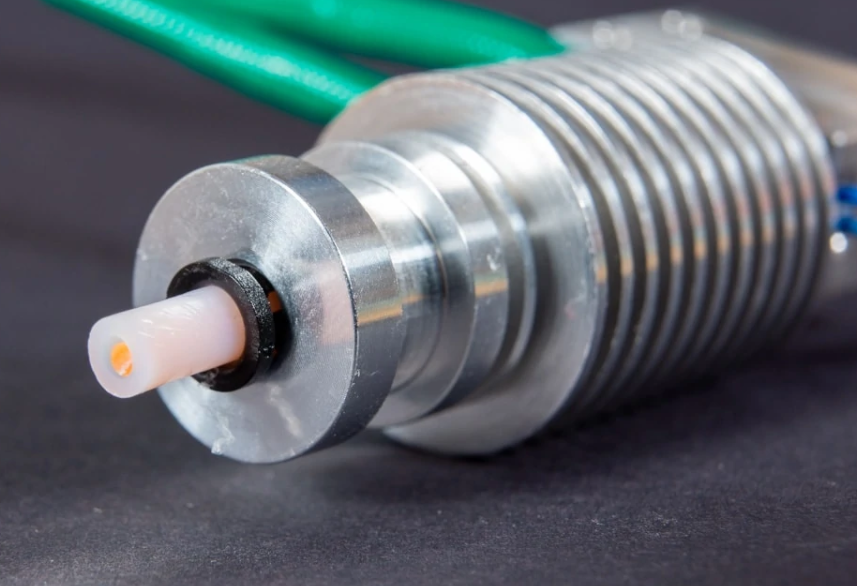

Gap at PTFE tube

A gap between the PTFE tube and the top of the nozzle can also cause problems. These gaps can be caused by an uneven end of the PTFE tube, when the tube is not pushed deep enough into the hotend, or when the nozzle is not screwed deep enough into the hotend to be flush with the tube. If there is a gap, the molten filament will fill it. And when the material cools, it completely clogs the hotend. This can happen both with hotends coated with PTFE material and with all-metal ones.

What is the solution?

First, remove the PTFE tube from the hotend (if possible), then screw the nozzle almost all the way in (about 95%). After checking that the PTFE end is straight and the PTFE coupling (which holds the tube) is screwed tightly into the hotend, slide the tube down into the hotend. And finally, screw the nozzle into the hotend enough to make a seal between it and the PTFE tube.

Exchanges and upgrades

If none of these solutions work, or you simply suspect that your nozzle is performing significantly worse and no amount of cleaning will help it, it may be time to get a new one. As mentioned earlier in the article, nozzles differ in material, diameter and other factors. These properties affect what the nozzle can do in terms of printing and how the prints turn out. For example, abrasive materials such as glow-in-the-dark materials or materials mixed with wood shavings significantly accelerate the degradation of inferior nozzles. Now it's time to talk about two important things to consider when replacing or upgrading the nozzle on your 3D printer. It is about diameter and material .

Basic nozzle dimensionsSize: 0.2 mmThe 0.2 mm diameter exit hole is among the smaller nozzles and allows you to print prints with greater detail. It's the perfect size for printing thumbnails. However, it is important to note that the print will take longer and will usually be weaker because it contains more print lines. Size: 0.4 mm0.4mm diameter is the standard for home 3D printer users. This size offers a great combination of print detail, power and print time. Size: 1.0 mmA nozzle with this diameter is one of the larger nozzles and allows you to print much faster. Prints should also be thicker as they will have fewer print lines, but this comes at the expense of print detail. |

|

Nozzle materials

Brass nozzleBrass is the most popular material from which nozzles are made and is also among the cheapest. But as you might expect, this material usually has the shortest lifespan because it breaks down the fastest. Brass nozzles are best suited for printing non-abrasive materials such as PLA, ABS and PETG. If you use a brass nozzle with abrasive materials, its life will decrease significantly faster. Approximate price per nozzle : approx. 30 CZK Popular brands : E3D, Biqu, Creality, Luter |

|

Steel nozzleSteel nozzles (including hardened and stainless versions) are a grade higher than brass nozzles. Nozzles made of this material are more expensive than brass nozzles, but have a longer life and a higher maximum temperature. In addition to non-abrasive materials, steel nozzles can also handle light use of abrasive materials without significantly damaging them. Approximate price per nozzle : approx. 80 CZK Popular brands : E3D, Creality, Micro Swiss, Afunta |

|

Ruby-tipped nozzleRuby nozzles are the absolute top among nozzles. The body of the nozzle is made of a conductive material (usually brass) and topped with a ruby tip. Since ruby is a gemstone that is extremely durable and resistant to damage, ruby tip nozzles can handle virtually any material and last for years. However, their disadvantage is the high price. Approximate price per nozzle : approx. 2,000 CZK Favorite brands : Olsson Ruby |