Gluing 3D printed parts

Why glue different parts of 3D prints?

The main reason is clear - some models from a 3D printer are too big to print in one piece. Other reasons include the fact that you want to complete prints from different types of filaments, from different colored filaments, or printing the model in one piece would be too complicated. Whatever your reason for having multiple pieces you'd like to put together, now is the right time to glue them together.

How to glue parts from a 3D printer?With the right procedure and choice of glue type, you can achieve 3D prints of almost invisible joints for glued parts. The general rule is that before you start gluing the parts, it is necessary to sand the glued surfaces, using coarser sandpaper (ideally on a solid surface - a cube), or a sanding sponge. If there is a larger joint, it can be sealed with the second-use adhesive itself. For example, ground source material (or dissolved in a chemical) can be used as a filler. As standard, however, we recommend the use of sealant or filler. |

|

Gluing according to the type of glue

Cyanoacrylate glue or Instant adhesives

|

In most cases, cyanoacrylate glue or instant glue will be the first and correct choice. Its advantages are obvious - it is easy to use, it cures extremely quickly, it forms a thin joint and it holds firmly. You can probably guess from the name that curing takes place within a moment, which could also be a stumbling block. Therefore, before you start gluing, make sure that you have everything ready - sanded and clean edges of the model and, above all, thought out what you want to glue with what. Be careful when the glue comes into contact with the skin, ideally use protective gloves when handling the glue, because the glue easily adheres to the skin. We recommend protecting the work surface as well. And ventilate when using glue. And it goes without saying that the glue must not get into the hands of children. You can use instant glue on most types of filament and the result will be great. But still, there is a filament that does not get along very well with instant glue. We are talking about flexible materials such as TPU/TPE. In the parts where the filament bends, the instant glue would not hold properly and the parts could break apart. |

|

The weak point of the glue is that its strength decreases in the cold and in high seconds, so it is not very suitable for models that should be in these temperatures. In addition to gluing, you can use the secondary glue to fill small imperfections on the model.

Procedure: first sand the edges smooth, then you can also clean the model with alcohol and let it dry (you should achieve a completely smooth and clean surface that is not greasy). Apply a little glue to the edges prepared in this way and hold the parts together for a few seconds. fix the model (for example with rubber bands afterwards) and let it harden completely. You can also grind the secondary glue and start the joint. But be careful - it's really very hard after it hardens, so it might not be that easy.

Suitable for fibers: PLA, ABS, ASA, PET-G, PC, CPE

Acetone

|

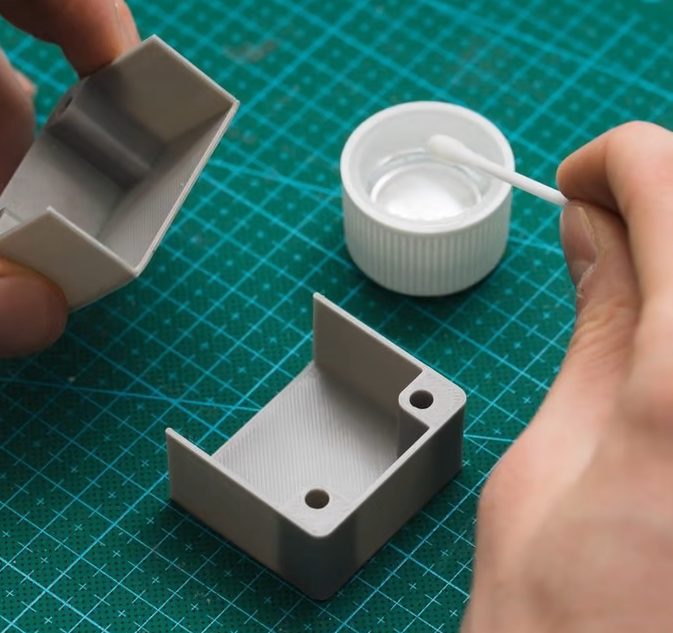

Gluing printed parts using acetone is another option that has its advantages and disadvantages. You can use it for all types of filaments that are soluble in acetone. The principle of gluing with this method lies in the fact that acetone etches the glued surface and creates a solid and almost invisible joint after curing. The downside is that since acetone bonding works by etching the material, you can't use it as a putty to smooth out joints and other imperfections in the print. The important thing is to precisely fit the sides that will be glued together. Don't use too much acetone, it could etch too much of the model on or around the glued side and damage the print (especially if you're gluing thin parts). Acetone evaporates during curing. Acetone is a flammable substance, so it is necessary to handle it with care and follow all safety rules - the area must be well ventilated, there must be no open flames, sparks and hot surfaces within reach. Acetone does not belong in the hands of children. In modeling circles, so-called ABS cement is used for bonding. This is an acetone-based glue and the same rules apply to it as we discussed with acetone. |

|

Procedure: Again, first clean and smooth the surfaces you want to glue, then apply a thin layer of acetone on them (you can do this with a cloth or a sponge, for example). Press the glued parts together firmly and fix it like this. You can use rubber bands, pliers or clamps. Let the model harden well. You can find a tip for a small vise that you can 3D print yourself here.

Suitable for filaments: ABS, ASA, HIPS

Epoxy or two-component glue

You may have heard of Epoxy in connection with post-processing, as it is often used to additionally smooth prints. We wrote about it in the article Tips for surface treatment of PET-G filament prints.

|

But in the case of two-component adhesives, you can safely use epoxy to glue several pieces of prints. It is already clear from the name that this is a material that consists of two components - resin and hardener. The two components must be mixed before use. The amount you prepare will depend on the size of the surfaces to be glued. The ratio of the mixed components is always indicated on the specific glue. We recommend keeping this ratio. Epoxy will work for most filaments, but will not be ideal for flexible materials as it hardens as it dries. Curing can take from a few minutes to several hours. It depends a lot on the chosen type and brand of glue. The advantage of glues that harden for a long time is that you have more time to arrange the glued prints. After hardening, you can further modify the epoxy (sand or even paint). |

|

Procedure: clean the glued surfaces, you don't need to sand them too smooth, because the epoxy glue also works well as a sealant and beautifully aligns imperfections. You can also apply epoxy glue in larger layers. Then wait for the model to harden completely.

Suitable for filaments: all filaments except flexible materials

PU (polyurethane) and silicone adhesives

|

Another possibility is the use of polyurethane or silicone glue, which will ensure a solid connection of the parts. Its advantage is that it is easy to work with and suitable for almost all filaments. The disadvantage is that a relatively large layer must be applied to the part in order for proper bonding to occur. And this will affect the final appearance of the prints. Avoid contact of the adhesive with the skin. There is a fairly large selection of silicone and PU adhesives on the market. It is therefore necessary to try which one will be ideal for your needs. |

|

Procedure: clean and smooth the glued parts, apply a sufficient layer of glue, fix the parts together and let it harden. The curing time depends on the type and brand of glue you use.

Suitable for filaments: almost all filaments

Melt gun

|

Gluing with a hot melt gun is relatively simple and the glue dries in a few seconds, so it is not even necessary to fix the glued parts together. The bad news is that you will need to apply more glue to the parts to bond, which may not be aesthetically pleasing. But even this can be at least partially solved if you glue the model from PLA material. It is possible to use PLA filament sticks printed on a 3D printer in the melt gun. Thanks to this, you can completely match the color of the filament of the glued part and the filament used in the melt gun. Be careful when applying the glue, the melt gun gets very hot during application and can cause burns. |

|

Procedure: clean and smooth the glued parts, apply a sufficient amount of glue with a heated hot melt gun and press the parts together. Wait a few seconds.

Suitable for filaments: PLA, ABS, PET-G

3D pen

|

If you have a 3D pen at home, you can try using it to glue individual parts together. The basic rule is: use the same material as the 3D pen refill from which the glued model is made. And of course it will be ideal if you also use the same color of filament. The disadvantage of this method of gluing is that the joints will not be very strong, so it will not be an ideal choice for stressed and functional models. |

|

Procedure: clean and smooth the glued parts, apply filament with a 3D pen and glue together. Let it harden.

Suitable for filaments: all filaments if you use the same filament for bonding and model.

Gluing according to filament type

|

Filament type |

Type of glue |

More information |

|

PLA filament |

ordinary instant glue |

You can use an activator to harden the glue faster. Fill larger joints with the remains of the filament or with filler for instant glues. Etching can be used to bond PLA. We use tetrahydrofuran or dimetal alcohol to etch PLA. However, substances cannot be used to smooth the part, as is the case with the combination of ABS/ASA and acetone (ABS juice). |

|

PET-G / PET |

ordinary instant glue |

You can use an activator to harden the glue faster. Fill larger joints with the remains of the filament or with filler for instant glues. Etching can be used to bond PET-G. We use tetrahydrofuran or dimetal alcohol to etch PET-G. However, the substances cannot be used to smooth the part as is the case with the combination of ABS/ASA and acetone. |

|

ABS / ASA |

ordinary instant glue |

You can use an activator to harden the glue faster. Fill larger joints with the remains of the filament or with filler for instant glues. ABS grinds better than PLA because there is no melting of the material during grinding. It is therefore more suitable for machine sanding on a belt. For gluing ABS and ASA materials, you can use acetone, which is commonly available in hobby markets. By dissolving the material in acetone, we obtain a so-called juice, which can also be used to seal smaller joints. |

|

Polykarbonátu (PC) |

ordinary instant glue |

You can use an activator to harden the glue faster. Fill larger joints with the remains of the filament or with filler for instant glues. It grinds better than other materials because the material does not melt during grinding and polycarbonate is relatively hard. |

|

CPE |

ordinary instant glue |

|

|

TPU/TPE - flexibilní materiály |

instant rubber glue |

Flexible materials are more difficult to bond. |

|

Nylon |

special adhesives |

Bonding usually requires the use of an activator (for example Loctite). |

|

PP |

special adhesives |

Bonding usually requires the use of an activator (for example Loctite). |