3D printing - everything you need to know

Find out here:

-

What is 3D printing?

-

Is 3D Printing Really Printing?

-

How does 3D printing work?

-

Who invented 3D printing?

-

What are the benefits of 3D printing?

-

What can 3D printers do?

-

What are 3D printing services?

-

Where can I buy a 3D printer?

-

What software do I need for 3D printing?

-

What is the future of 3D printing?

What is 3D printing?

At its most basic, 3D printing is a manufacturing process in which material is laid down layer by layer to create a three-dimensional object. (This is considered an additive process , because the object is built from scratch, as opposed to subtractive processes , in which the material is cut, drilled, milled, or machined.)

Although 3D printers use different materials (such as plastic or metal) and techniques , they share the ability to convert digital files containing three-dimensional data - whether created in a computer-aided design ( CAD ) or computer-aided manufacturing ( CAM) program , or from 3D scanner – to physical objects.

Is 3D Printing Really Printing?

Yes, 3D printing can be considered printing, although not as traditionally defined. Relevant definitions of "press" focus on:

- print production,

- publications or

- photographs

- manufacturing using an impression (pressure application)

Neither of these definitions fit 3D printing. But from a technological point of view, 3D printing is an outgrowth of traditional printing, where a layer of material (usually ink) is applied. It is usually so thin that the height is not noticeable (although it is somewhat thicker on solid ink printers).

What 3D printing does is greatly expands this height of applied layers. So it would make sense to expand the definition of printing to include the production of three-dimensional objects in this way.

How does 3D printing work?

|

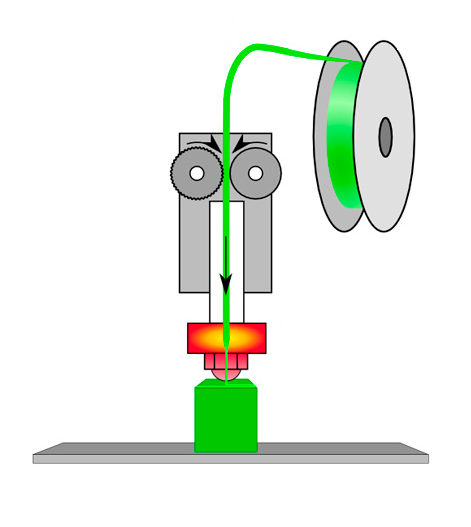

Similar to traditional printers, 3D printers use different technologies. The most commonly known is "fused deposition modeling" (FDM) , also known as "fused filament fabrication" (FFF) . In it, the fiber / filament / printing string - composed of acrylonitrile butadiene styrene (ABS) , polylactic acid (PLA) or another thermoplastic - is melted to a given temperature and applied through a heated nozzle in layers. The first 3D printers to hit the market, made in the mid-1990s by Stratasys with help from IBM, used FDM (a Stratasys trademarked term), as did most consumer, hobbyist, and school 3D printers. |

|

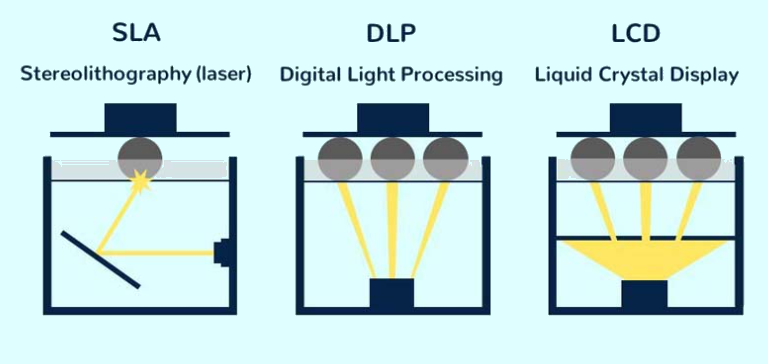

| Another technology used in 3D printing is " stereolithography" (SLA) . In it, a UV laser is shone into a vat with a photopolymer sensitive to ultraviolet radiation, and the object to be created is outlined on its surface. The polymer solidifies wherever the beam touches it , and the beam "prints" the object layer by layer as instructed in the CAD or CAM file to prepare the file for the printer. | 3D printing "digital light projector" (DLP) is also similar to this technology . This method exposes the liquid polymer to light from a digital projector. This cures the polymer layer by layer until the object is built, and the remaining liquid polymer is drained. | Another variation of this technology is "liquid crystal display" (LCD). This method also uses a projector, but between it and the tub of resin is an LCD display that transmits light only where the polymer is to be etched. |

|

||

|

Multi-jet modeling is an inkjet 3D printing system that sprays a colored glue-like binder onto subsequent layers of powder where the object is to be molded. This is one of the fastest methods and one of the few that supports multi-color printing . HP is especially impressive with this technology. |

|

It is also possible to modify a standard inkjet printer to print with materials other than ink. Enterprising DIYers have built or modified print heads, generally piezoelectric heads, to work with different materials – in some cases printing the print heads themselves on other 3D printers! Companies like MicroFab Technologies sell 3D print heads (as well as complete printing systems).

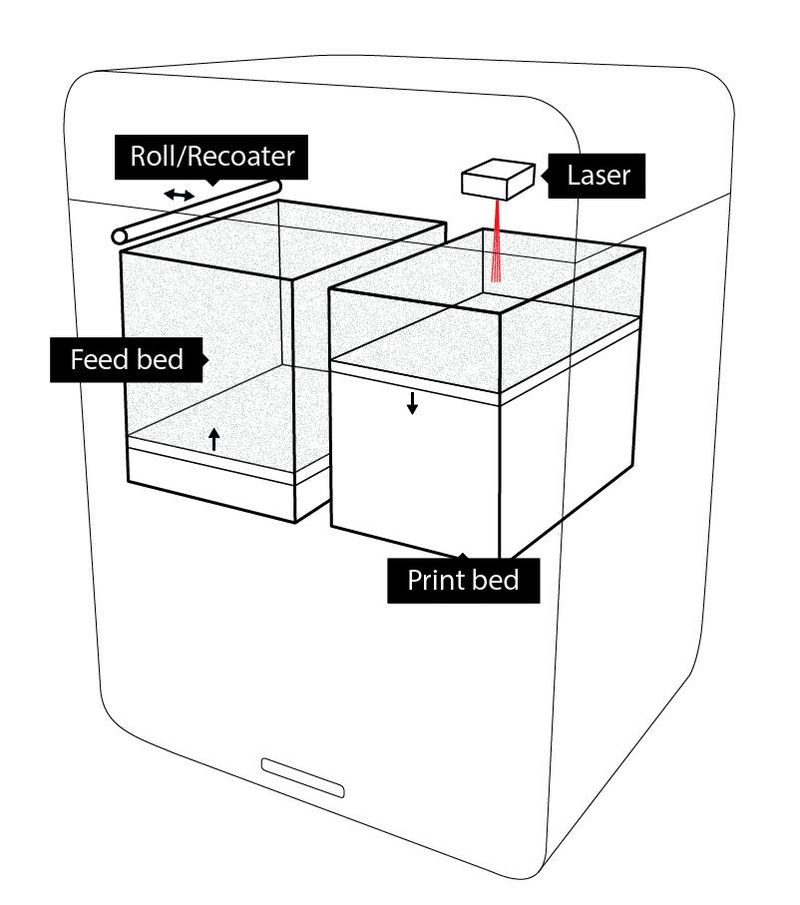

| The most useful technology is "selective laser sintering" (SLS) , which uses a high-power laser to join particles of plastic, metal, ceramics or glass . At the end of the work, the remaining material is recycled. Electron beam melting (EBM) uses an electron beam to melt the powder, layer by layer. Titan material is often used with EBM to print medical implants as well as aircraft components. |  |

Depending on the technique, 3D printers can use a variety of materials, including metals (among them stainless steel, aluminum, and titanium); plastics and polymers (including composites that combine plastics with metals, wood and other materials); ceramics; glass; and even foods like cheese, frosting and chocolate! (See our primer on 3D printer filament types.)

Who invented 3D printing?

The first 3D printer to use the stereolithography technique was created by Charles W. Hull in the mid-1980s.

Stereolithography has traditionally been an expensive commercial technique, costing in the five and even six figures, but in recent years there have been desktop stereolithography printers costing several hundred thousand, as well as consumer systems starting well below the thousands.

In 1986, Hull founded 3D Systems , a company that today sells 3D printers using a variety of technologies. Ranging from basic kits to advanced commercial systems, 3D Systems also provides spare parts on request, mostly to business customers.

What are the benefits of 3D printing?

Thanks to 3D printing, designers have the opportunity to quickly transform concepts into 3D models or prototypes ( "rapid prototyping" ) and implement rapid design changes . It allows companies to manufacture products to order on a one-to-one basis rather than in large series, which improves inventory management and reduces storage space requirements. People in remote locations can craft items that would otherwise be unavailable to them.

From a practical point of view , 3D printing can save money and material compared to subtractive techniques because very little raw material is wasted. And it promises to change the nature of manufacturing, eventually allowing consumers to download files to print even complex 3D objects – including, for example, electronic devices, enabling printing in their own homes.

What can 3D printers do?

- Designers use 3D printers to quickly create product models and prototypes, but they are also increasingly used to produce final products.

- Items made with 3D printers include, for example:

- The automotive and aerospace industries also use 3D printers to produce parts.

- Mainly due to cost reduction

- Artists can create sculptures and architects can make models of their projects.

- Archaeologists are using 3D printers to reconstruct models of fragile artifacts, including some antiquities that have been destroyed by ISIS in recent years.

- Likewise, paleontologists and their students can duplicate dinosaur skeletons and other fossils.

- Doctors and medical technicians can use 3D printing to make prosthetics, hearing aids, artificial teeth and bone grafts, as well as replicate models of organs, tumors and other internal body structures from CT scans in preparation for surgery.

- A good example is Project Daniel, which is 3D printing prosthetic arms and hands for victims of violence in Sudan. Also being developed, 3D printers that can lay down layers of cells to create artificial organs (such as kidneys and blood vessels) are already in the research and development phase. In forensic practice, there is even a place for 3D printing, for example to replicate a bullet trapped inside a victim.

- Printed electronics is a set of printing methods that allow electronic devices or circuits to be printed on flexible materials such as labels, fabrics and cardboard by applying electronic or optical inks. It provides very cheap production of low power devices. Printed electronics are starting to combine with 3D printing, which allows the printing of layered circuits or devices. The natural consequence of this powerful combo is that one day you may be able to print gadgets from 3D plans rather than buying them.

- Food preparation is another way 3D printers can be used.

- The French Culinary Institute uses the Fab@Home open-source 3D printer developed at Cornell University to prepare artistic delicacies.

- MIT has also created a 3D food printer called Cornucopia. A small number of restaurants are testing food printer prototypes.

- NASA's 3D printing research has included food printing, such as 3D printing pizza.

- A handful of food 3D printers have become commercially available. They tend to focus on specific foods such as chocolate, pancakes or cookies.

What are 3D printing services?

You don't need to own a 3D printer to benefit from it. Many 3D printing services, such as 3DWiser and Pruša, print to order on their own 3D printers and then ship them to the customer. Customers can either submit their own 3D object files or choose items, mostly designed by other users of the service, from an online catalog.

But 3D printing services are no longer just the domain of specialists. Major companies like UPS have introduced 3D printing services, and some traditional printers have added on-demand 3D printing to their repertoire.

Where can I get a 3D printer?

Most 3D printer manufacturers sell their products directly online. Many online stores now stock them, including online-only companies and others that also have brick-and-mortar stores. Some of them, such as this e-shop, offer them in stores and online, but do not forget to check the availability of printers, for example on our chat.

What software do I need for 3D printing?

Almost all 3D printers accept files in the so-called STL format (named after stereolithography). Most any CAD software can create these file types , from expensive commercial packages like AutoCAD to free or open source products like Fusion360, Google SketchUp, and Blender . For those who don't want to create their own 3D files, 3D object databases such as MakerBot Thingiverse offer numerous 3D object files that can be downloaded and printed.

Most 3D printers come with a software package that either comes on a disc or is available for download that contains everything you need to print. Kits typically provide a printer control program and a slicer that formats the object file into layers based on the chosen resolution and other factors in preparation for printing . Some kits include a program to "repair" a file / object that could interfere with smooth printing - this is, for example , the Netfab service . The programs emerged from the open source RepRap movement, which evolved into hobbyist 3D printing. With some printers, you can choose individual components to download rather than using anything that comes with the kit.

What does the future of 3D printing bring?

A number of home and small business 3D printers are readily available, but they are still often considered exotic and rather expensive gadgets. Expect that to change over the next few years as 3D printers become more commonplace in homes – found on desks, in studios, in home offices, and even in the kitchen. You may not find them in every home, but they become indispensable to people who have them.

Prints made on 3D printers have more so far, but we will start to see more complex creations combining multiple materials and composites, as well as printable electronics. If you lose your TV remote battery cover with today's 3D printers, a replacement cover can be printed. With tomorrow, if you lose your driver, you might be able to print a brand new driver.

3D printing is also gaining a foothold in space. NASA is experimenting with 3D printers aboard the International Space Station. Eventually, 3D printers could be used to create habitats on Mars and other worlds. In order to save the Apollo 13 astronauts from death by carbon monoxide suffocation, NASA actually had to find a way to fit a square peg into a round hole. If there was a 3D printer on board, they might have been able to easily solve the problem by designing and printing the connector.

Astronauts can't swing by Home Depot if they need to replace a valve or widget, but a 3D printer could make them as needed. Similarly, we will see 3D printers in Antarctic bases and other remote Earth locations where people cannot wait six months for another supply to replace essential parts or tools.

The medical applications of 3D printing do not end with prosthetics, hearing aids and dental crowns. Spare parts need not be limited to mechanical parts. In the last few years we have seen an explosion in the variety and use of 3D printers. It's similar to where personal computers were around 1980. While it's easy enough to see some areas that the field of 3D printing will branch into, others are beyond our ability to foresee, just as no one in 1980 could have imagined much of it , what the personal computer would turn into. 3D printing may not have the same impact on consumers in everyday life as PCs, but it has the potential to revolutionize manufacturing and, perhaps more importantly, bring it into the hands of everyday consumers. However, one thing is certain: 3D printing is here to stay.